After dropping the engine back in place last week I generally took my time about getting the heavy gauge battery and starting wires, along with the fuel lines upgraded. Some of the old heavy gauge wire was second rate 2/0 welding wire and really far from a marine grade product. It truly makes a difference.

All the heavy gauge wire coming from.... the starting battery, AC inverter, windlass, alternator ground, were all bunched up on the load side of a shunt measuring amps, voltage and consumption of power through an electronic device called a Link 10. A great tool to monitor the DC power on the boat.

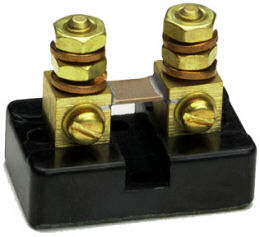

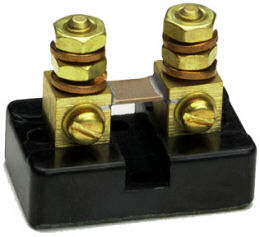

The problem I bought with the boat is, I had too much all bunched up, that should have been separated from the shunt, the power shunt is only a device for measuring power through the two posts, not something to replace a buss bar. The two little screws let the Link 10 attach, so it can monitor all the power going through the two large lugs. I had like 6 wires all bunched up on one side of that. Actually....there was large wire from the inverter on the wrong side, which should only be one wire directly to the house battery bank, so the Link 10 was not reading the inverter's consumption from the battery bank when it was operating

|

| Shunt |

|

| Buss bar |

Like I said, there were a few things I had to sort out with the help of a paid professional and some local knowledge before I called this a done deal. When the engine is out.....the little worker bees need to get as much done as they can before the Westerbeast gets settled back in place. I needed to add a buss bar and separate my bonding wires that were haphazardly attached to the engine and the shunt. Needed a "clean up".

So here is the shunt at the top of the picture, then a 2/0 wire connecting to the buss bar where all the negatives connect and then it also connects to the bonding wires which I admit is not a great set up but I didn't have another bus bar and there is so much controversy about bonding things on a boat, and all the info I was told and all the info I saw on the internet....SHEESH! I figured I'd make do with what "I" feel should be OK.

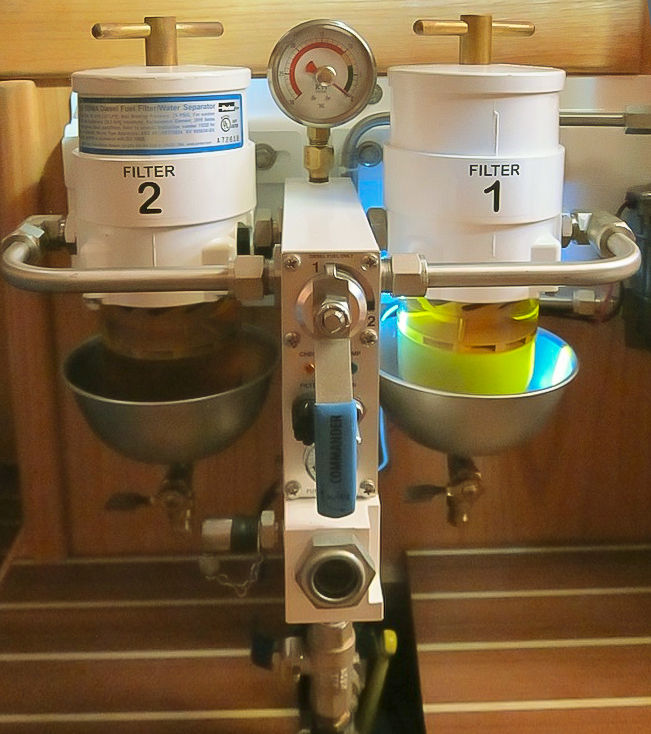

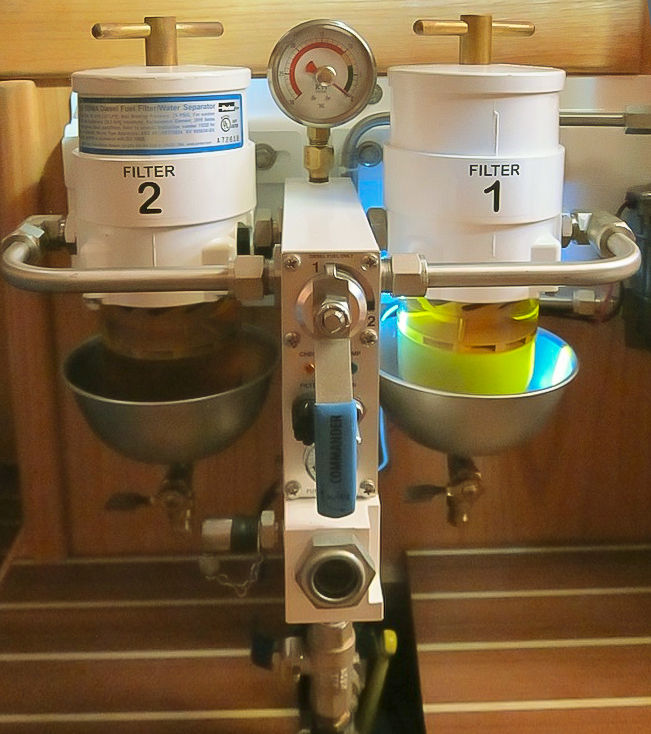

This whole project was brought on by the fact that the fuel system and tank had failed. I would have liked to have had the time and mind-set to develop a completely new fuel polishing system with two filters, by-pass lines and fuel pump, but couldn't gather it all in while trying to live here and just get the damn job done. What I did do is, installed all new fuel lines and fittings from tank to engine well secured every 18"'s and positioned out of the way so I can construct a new fuel boss type system that I will build myself and insert (when I find the time, you know!).

|

| A fuel filtering system |

|

| All neat and tidy. |

BUT THE BIG NEWS.......is the engine is all hooked up and running. I got it up to temperature and have the coolant full. A few more doo daa's, new fuel gauge and sender coming in the mail but nothing stopping me from getting the boat back into 100% guest friendly, neat and tidy, take the tools out and put the tools back type of work!!!!!!! It's been a hard road taking out the engine and planting it in the middle of our living space, which disrupts the whole living on a boat scene to repair a leaking fuel tank but these evils we got by, and still live day to day, still in love, on our floating "Painkiller" Not to mention....Vero Beach...does NOT suck!

Shunt is a funny word.

ReplyDeleteThis post made my head hurt, your like an Einstein dude with your shunts and buss bars and such, reminded me of my advanced physics class. I Like the happy ending part.

ReplyDelete